Pulsed Laser Deposition (PLD) - Abstract

Pulsed-laser deposition (PLD) has gained a great deal of attention in the past few years for its ease of use

and success in depositing materials of complex stoichiometry. PLD was the first technique used to successfully

deposit a superconducting YBa2Cu3O7 thin film. Since that time, many materials that are normally difficult to

deposit by other methods, especially multi-element oxides, have been successfully deposited by PLD.

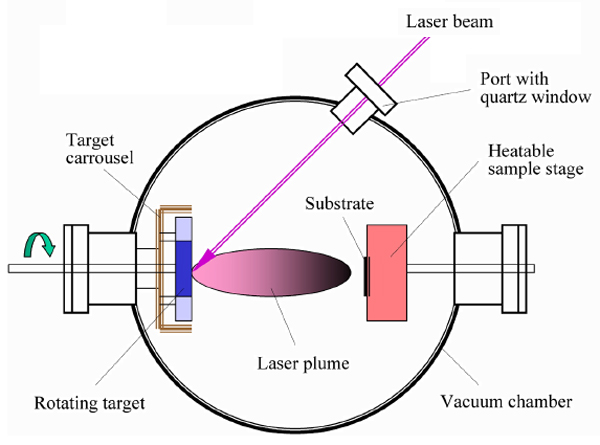

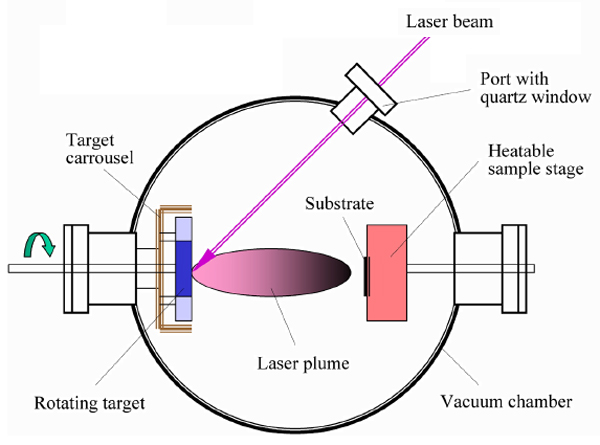

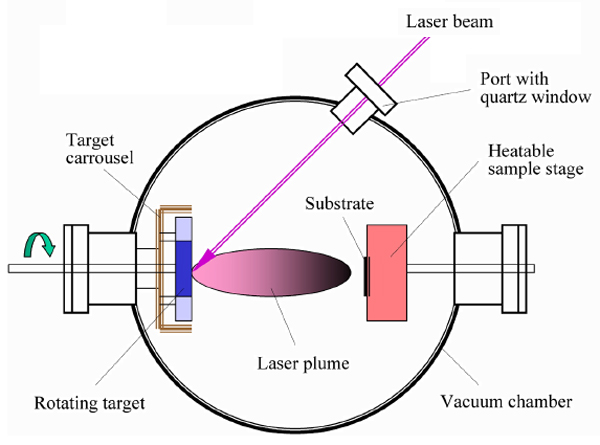

Schematic view of a PLD-System

The main advantage of PLD derives from the laser material removal mechanism; PLD relies on a photon interaction

to create an ejected plume of material from any target. The vapor (plume) is collected on a substrate placed a short

distance from the target. Though the actual physical processes of material removal are quite complex, one can

consider the ejection of material to occur due to rapid explosion of the target surface due to superheating.

Unlike thermal evaporation, which produces a vapor composition dependent on the vapor pressures of elements in the

target material, the laser-induced expulsion produces a plume of material with stoichiometry similar to the

target. It is generally easier to obtain the desired film stoichiometry for multi-element materials using PLD than

with other deposition technologies.

The main advantages of Pulsed Laser Deposition are:

- conceptually simple: a laser beam vaporizes a target

surface, producing a film with the same composition as the target.

- versatile: many materials can be deposited in a wide variety of gases over a broad range of gas pressures.

- cost-effective: one laser can serve many vacuum systems.

- fast: high quality samples can be grown reliably in 10 or 15 minutes.

- scalable: as complex oxides move toward volume production.

On the following pages we give a short review on PLD techniques, the historical development,

the physics behind these techniques and a brief presentation of our home-made PLD-system in action.